Onboarding Semester

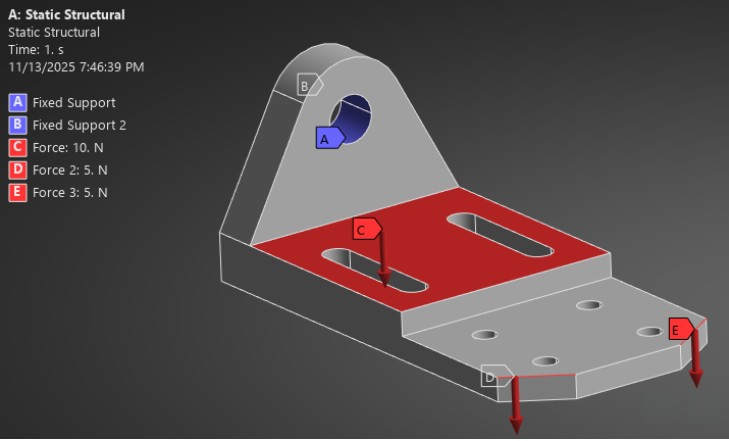

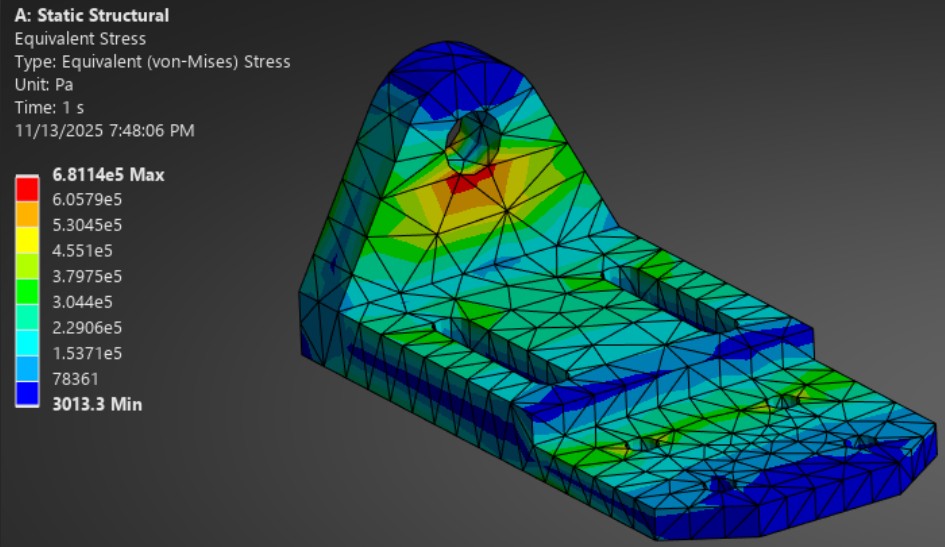

In my second semester of freshman year, I joined Cornell Hyperloop on the Structures Subteam of the Mechanical Team. As part of the freshman onboarding we were brought up to speed on SolidWorks and ANSYS. I had been CADing for about five years prior to that, so SolidWorks was easy to adapt to. They had us create a 3D part using a technical drawing. ANSYS was new and interesting to learn. They had us pin the part we made in certain positions and apply loads at certain points. We then looked at the gradient and the maximum stresses at different parts of the object to determine things like failure points and factor of safety.

Main Project:

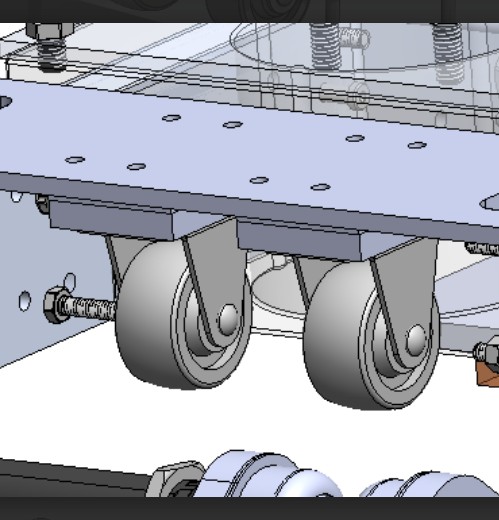

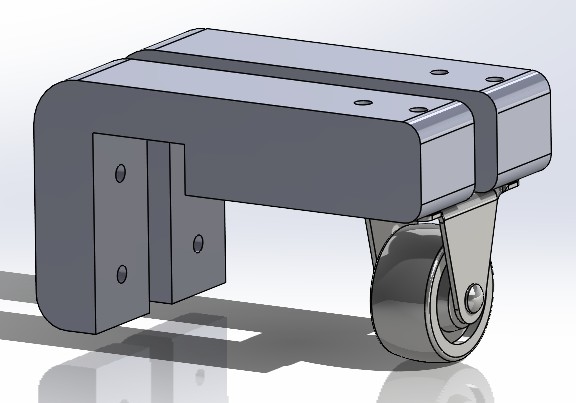

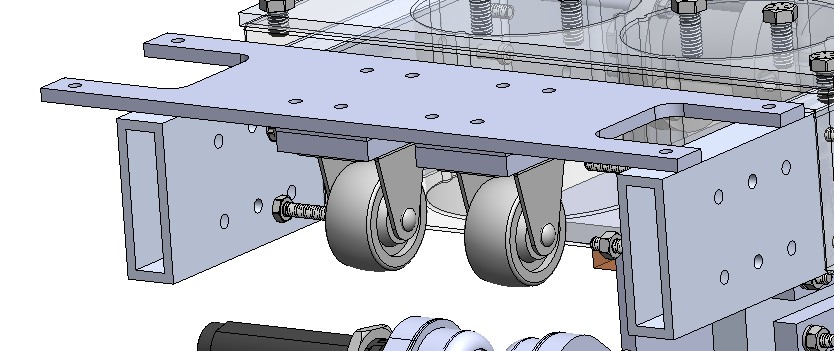

My primary freshman project was to design a guidance structure and choose wheels for it that would attach to the frame of the chassis and hold up the pod on top of the track that it rests on. This was a simple project and although my design was technically fine, I made it more complex than necessary. I created an irregularly shaped part with chamfers that would wrap around the chassis bars and two of them would be required for each wheel. What I made was something more likely to be CNCed than the design we went with in the end.

The design we implemented was basically a large plate with sections cut out and holes for screws in it. Everything could be done on one of the Bridgeport mills within the machine shop. No fuss no muss. This was a good lesson in simplicity sometimes being key.

The design we implemented was basically a large plate with sections cut out and holes for screws in it. Everything could be done on one of the Bridgeport mills within the machine shop. No fuss no muss. This was a good lesson in simplicity sometimes being key.

Other Projects:

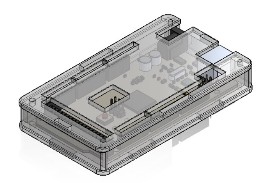

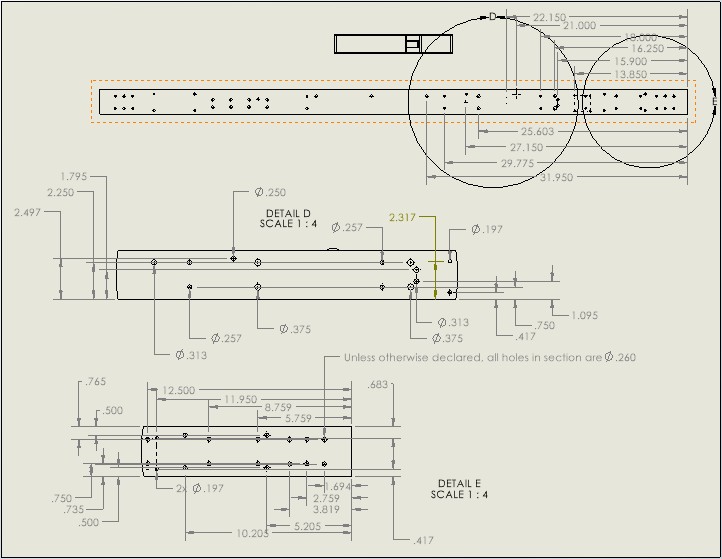

Besides working on our assigned main projects, freshmen were tasked with creating enclosures for electrical components that would be on the pod. Based on an alarm clock I had made before with an acrylic enclosure, I made an enclosure for my given component that consisted of acrylic pieces that would fit into one another. I had experience with creating and dimensioning techincal drawings, so I was allowed to assist in dimensioning and drafting part drawings for our pod’s chassis that would be sent to a company to both weld the chassis bars the way we wanted and drill the holes for us. The only reason we did not due this in house was due to a lack of members with welding experience, and requiring precision holes drilled into the carbon steel frame.

Besides working on our assigned main projects, freshmen were tasked with creating enclosures for electrical components that would be on the pod. Based on an alarm clock I had made before with an acrylic enclosure, I made an enclosure for my given component that consisted of acrylic pieces that would fit into one another. I had experience with creating and dimensioning techincal drawings, so I was allowed to assist in dimensioning and drafting part drawings for our pod’s chassis that would be sent to a company to both weld the chassis bars the way we wanted and drill the holes for us. The only reason we did not due this in house was due to a lack of members with welding experience, and requiring precision holes drilled into the carbon steel frame.

Technologies Used: SolidWorks, ANSYS, Google Slides

Back to Projects